Blog

The Art of Sealing Cracks With Backer Rods

November 18, 2024

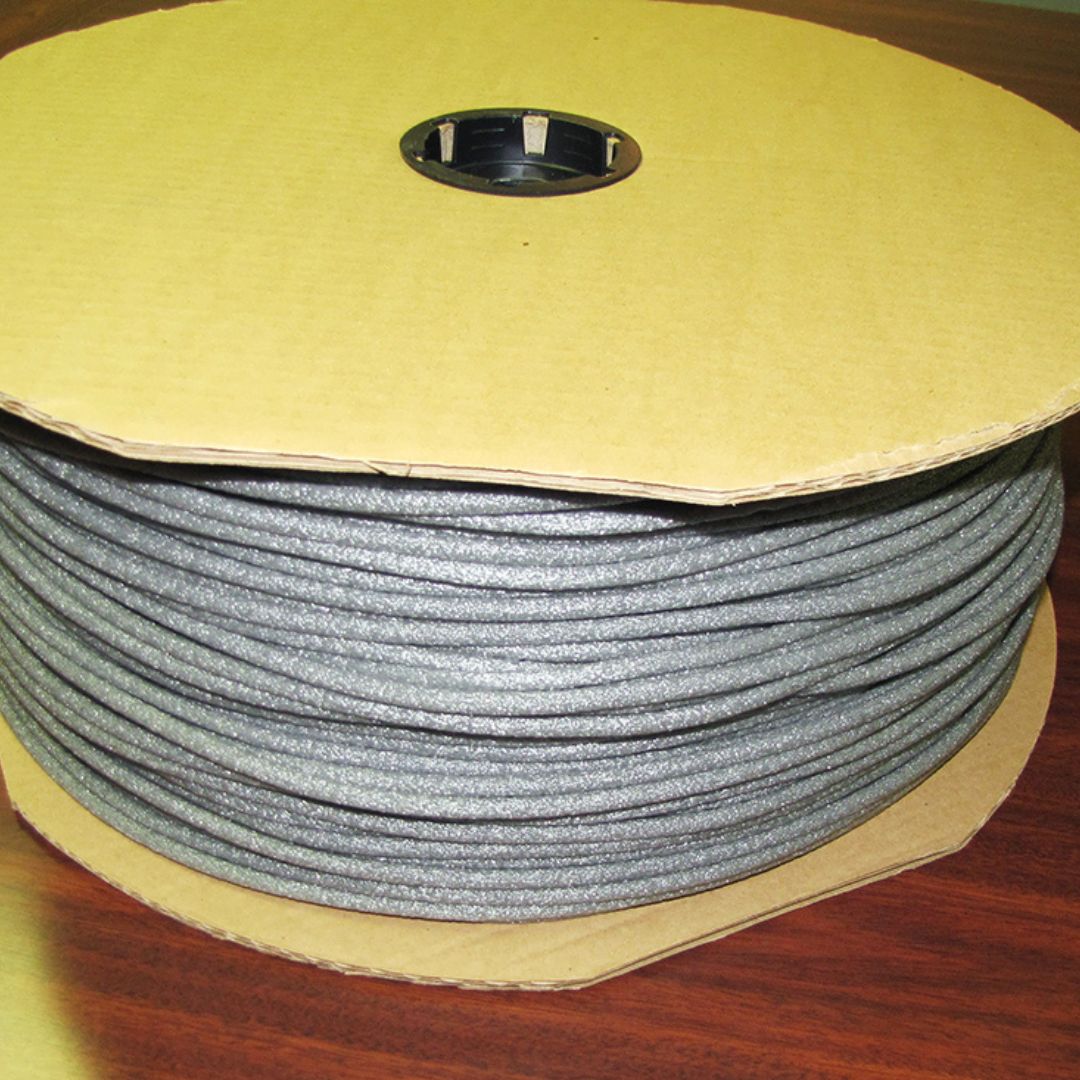

Even the strongest structures might wither with time. The occasional appearance of cracks on walls and joints is pretty common. However, if the cracks are left untreated, they could become an issue. Thankfully, backer rods exist. They are long, cylindrical, flexible rods used to seal cracks. Alcot Plastics Ltd. manufactures top-notch PE foam rods. Polyethylene foam is the perfect material for this owing to its exceptional water and moisture resistance. It prevents water from seeping into cracks and compromising the structural integrity. In this blog, we discuss the art of sealing cracks with backer rods.

Sealing Cracks With Backer Rods Is Simple and Effective

Backer Rod-Sealant Combination

While the foam roads are highly effective, they are often used in conjunction with sealants. The flexibility and absorption ability of the rods work well with sealants. These rods facilitate depth control. Meaning, they ensure the sealant layer is not too deep or shallow. This ensures perfect sealing of cracks and prevents peeling and cracking. Backer rods also prevent three-sided adhesion. Two-sided adhesion enables the sealant to expand without cracking.

How To Do It?

To seal cracks on walls and pavements, all you need is a backer rod and good-quality sealant. Ensure the rod is of the correct dimension. It is essential to source custom rods to ensure a snug fit. We at Alcot Plastics Ltd. manufacture foam rods to meet your specific requirements. Squeeze the rod tightly within the crack. You can use your fingers or a blunt tool to push the rod in. Once it’s secured, pour the sealant over the rod to complete the task.

Conclusion

Fixing wall cracks with backer rods and sealants is that simple. For all your polyethylene foam product needs, think of Alcot Plastics Ltd. Our facility in Guelph, Ontario is equipped with state-of-the-art machinery. The special extrusion technique envisioned by our founder guarantees quality. Call 519 767 2899 to place an order.